Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

Main Equipment For Fresh potato chips processing line:

1.Potato washing and peeling machine: integrates the function of washing and peeling, and it can be used for processing potatoes, carrots, radish, sweet potatos and other root vegetables.

2. Potato slicing machine: used for cutting the potatoes into slices, strips or cubes and also suitable for other root vegetables, like carrots, cassava etc

3. Potato slice blanching machine: used for blanching the slices, strips or cubes of potatoes or any root vegetables. The main purpose of blanching is to remove potato starch and ensure the slices brightness and crispy.

4. Potato dewatering machine: adopts centrifugal principle to dehydrate. This step is prepared for the frying part, which shortens the frying time and perfects the taste of the potato chips, potato crisps or French fries

5. Potato slices frying machine: adopts oil-water mixing technology, so the sediment can be cleaned easily. Besides, the service time of the oil is prolonged and the cost is cut largely by taking use of the oil-water mixing technology.

6. Potato chips de-oiling machine: widely used for extrude the extra oil of the fried food to ensure the potato chips taste good and more healthy for human

7. Potato chips flavoring machine: used for seasoning the fried potato chips. Which flavor is needed totally depends on customer.

8. Potato chips packing machine: improves the packing efficiency and saves a lot of time. As fried potato chips are fragile, the nitrogen is necessary to keep food fresh, tasty and without damage.

1. Different model to meet different output capacity requirements and special requirements can be customized.

2. Flexible configuration to satisfy different budget and workshop area requirements.

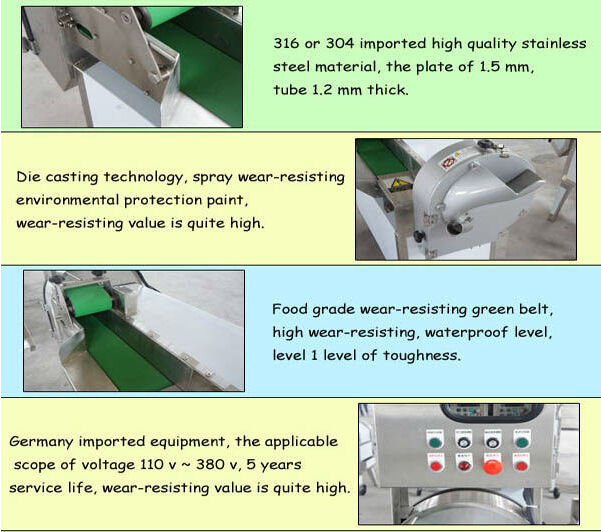

3. Adopt food-grade 304 stainless steel to ensure long service life, neatness and easy clean.

4. Thickness of potato chips and French fries can be adjusted according to customer requirements.

5. Frying machine with oil-water mixing technology, which can clean the sediment easily, so as to extend oil change period, save cost largely and ensure good frying taste.

Parameter

| Model | Power | Output | Size |

| FLD-P 150 | 80KW | 100-150KG/H | 18000*2000*2500MM |

| FLD-P300 | 140KW | 200-300KG/H | 20000*2100*2500MM |

| FLD-P 500 | 180KW | 300-500KG/H | 23000*2100*2500MM |

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.