Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

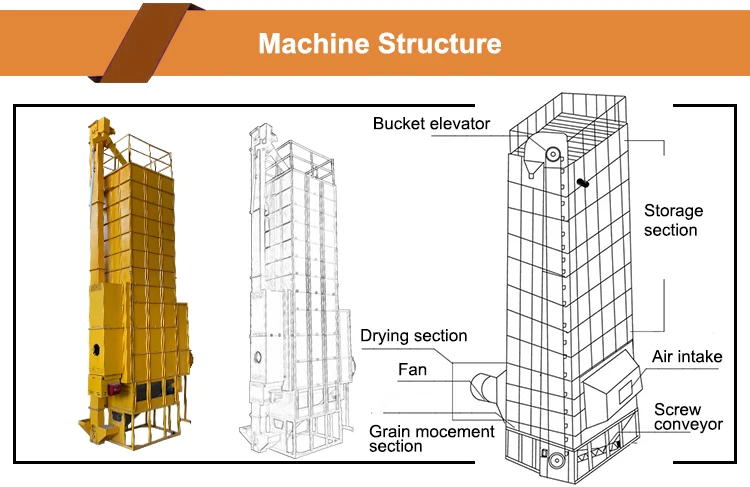

Product Description of Grain Dryer

This machine is mainly used for drying grain. Drying grain belongs to continuous work. It has higher requirements on the stability and continuous operation of the dryer during use. The material requirements for the material selection and wear parts of the dryer are very high. The batch type circulating dryer produced by our factory belongs to the low-temperature energy-saving drying equipment. It has the characteristics of convenient installation, simple operation, low noise, low energy consumption and low power. It mainly dries high-quality grain and meets user needs.

Application of Grain Dryer

Rice, wheat, barley, buckwheat, barley, corn, soybean, mung bean, broad bean, red bean, black bean, sorghum, millet, rapeseed, sunflower seed, etc.

Features of Grain Dryer

1. High height drying layer. The drying layer is 2.7 meters high, 1.3 meters higher than other type grain drying equipment,the drying output is large and the effect is good.

2. Stainless steel internal material. Our grain dryer internal material is made of 316 stainless steel, which is clean and has a long service life.

3. Painted body. The grain dryer uses the electrostatic spray coating paint process, which has the characteristics of heat resistance, wear resistance and corrosion resistance.

4. Simple operation. It takes more than 4 people to work when operating other types of grain dryers; our grain dryers only need one person to work.

5. Drying effect is good. When drying the grain, the drying effect is ensured to be uniform, and the grain breaking rate is low, and the wheat fiber structure is not damaged when the wheat is dried.

Model | FLD-10 | FLD-20 | FLD-35 |

Dryer Type | Batch type recirculating | ||

Processing Capacity | >800 kg/h | >800 kg/h | >800 kg/h |

Dryer Volume | 20 m3 | 37.5 | 62 |

Overall Weight | 4000 kg | 6000 kg | 9500 kg |

Overall Dimension | 2900*4050*10500mm | 2900*4050*12200mm | 3500*4400*13330mm |

Power | 6.5 kw | 10 kw | 15 kw |

Fuel | Coal,Rice Husk,Wood Chips,Gas,Diesel,ect | ||

Reduction Moisture | 0.5-0.8 %/h | 0.5-0.8 %/h | 0.5-0.8 %/h |

Advantage of Grain Dryer

1. Custom base. When drying larger grain cereals, choose the self-flowing circulation base; when drying the grain with smaller specific gravity, use the base of replace spiral conveyor.

2. Dry all directions. Our grain dryers use a unique air intake method to allow even air to be evenly distributed in every corner,ensure the quality of dried grain.

3. High water evaporation rate.When the seeds are drying, the water evaporation rate can reach 0.8% and the germination rate is 86%. Other type grain drying equipment can only reach 0.7% and the seed germination rate is not guaranteed.

4. High efficiency and energy saving. If we use coal to dry, our grain dryer only needs 20-25 kg per hour, but other types of dryers need at least 200 kg of coal per hour.

5. No need to clean up the adjustment. Other type grain dryers are not ideal because of the drying effect, so adjustments are required,each adjustment takes about 3-6 days; our grain dryer does not need to be adjusted.

6. Drying water is easy to control. Other type grain dryers are not enough to dry the grain, and some grain is burnt, but some of the grain is still very moist. Our grain dryer will automatically stop after setting the dry water, which will not cause burntness.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.