Tel:+86-15264102980 Mob:+86-18660429170 Whatsapp: 8615264102980

1.Pasta Macaroni Production Line Introduction:

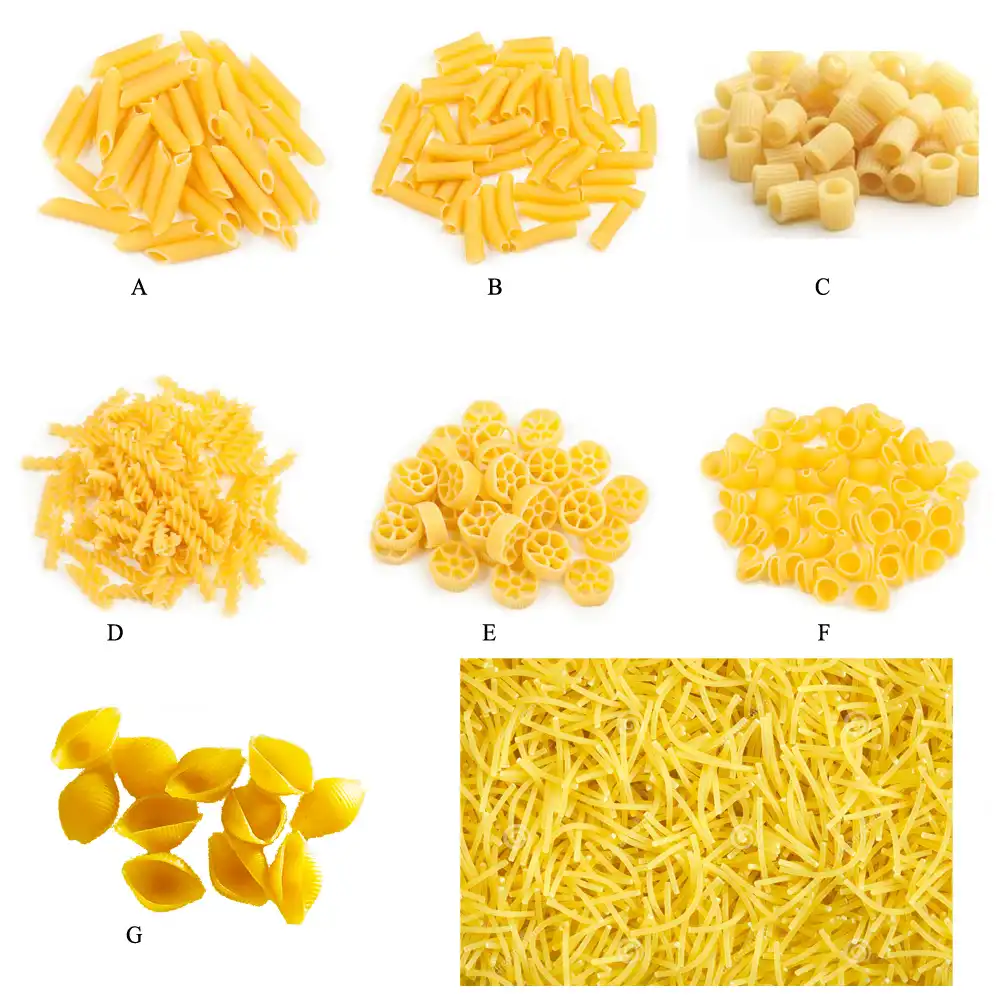

This Hot Sale Pasta Macaroni Making Equipment Machine Line is produced by single-screw extruder through extruding cooking. Assembled different moulds, the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the macaroni pasta needs frying to get expanded.Pasta and macaroni is a universal product consumed worldwide. The systems are designed to comply with the most demanding standards of hygiene, flexibility, consistency, productivity, and maintenance. Saibainuo systems maintain high-quality standards from start to finish, with perfect dosing of ingredients, homogeneous mixing, forming and cutting, drying, cooling, storage, and packaging.

2.Technical Parameters:

Model | Install Power | Real Power | Capacity | Dimension | Delivery |

DLG110 | 105KW | 73KW | 120-150kg/h | 22x 2.0 x 3.0 | 35 |

DLG150 | 190KW | 135KW | 250-300kg/h | 30x 2.0 x 3.0 | 40 |

DLG160 | 250KW | 175KW | 350-400kg/h | 35x 2.5 x 4.2 | 55 |

3.Macaroni food processing line Flow Chart

Mixing system---Extrusion system----Cutting system---Drying system---Cooling system--Packing system

4.Product features:

Here are some advantage of gluten free macaroni machine.

*High automation with easy operation

*Stainless steel material ensuring high quality of machine

*Durable single screw can use much more time

*Self cleaning without disassembling

*PLC control banal to control each machine directly

*Precise temperature control and display

5.Services:

*Consultation service before, during,and after sales;

*Project planning and design service;

*Debugging of equipment until everything is functional;

*Management of equipment' long distance shipping from seller's factory to the named place by buyer;

*Training of equipment maintenance and operating personally;

*New production techniques and formulas;

*Provide 1 year complete warranty and life-time maintenance service.

Tel:+86-15264102980

Mobile:+86-18660429170

Email: kevin@fldmachine.com

Whatsapp: 8615264102980

Copyright 2026 © Jinan FLD Machinery CO.,LTD All Rights Reserved.